We produce WORKTOPS that are very resistent on the surface, waterproof from the edge, and half-light from other alternatives for ease of transport.

Front surface and all edges are specially produced 1.5 mm. thickness of the exterior compact laminate, 1.5 mm polystyrene material coated on the bottom surface of MDF panels with honeycomb filler perfectly integrated all together, the edges are processed with flawless edge banding technology to provide waterproofing to our customers.

We dimension the worktops according to your project, cover the 4 sides with our special technology and cover the surface with compact laminate. In accordance with your request, we open the oven and sink spaces in CNC machines and make the edges of the openings waterproof.

STOCK COLORS

1- C901 White

2- C657 White Granite

3- C666 Anthracite Granite

MOPAŞ MOBİLYA ÜRETİM VE PAZARLAMA A.Ş.

ERMETAL DENTAL LTD. ŞTİ.

TALAT BERKALP

DOĞU MOBİLYA

AL SAGER CONSTRUCTION

RETAILER SALES

ÇEVİK ORMAN ÜRÜNERİ A.Ş.

Primarily, we should define what Seamless Edge Banding Technology is.

SEAMLESS EDGE BANDING TECHNOLOGY

This technology which is defined as Seamless edge banding has been created by German Wood Working Machinery Companies in 2009.

This technology is based on integration of similar color pre-glued edge bands with the pieces by the help of Laser beam. Subsequently, plasma, heat transfer methods have been started to be used for this purpose.

FLAWLESS EDGE BANDING TECHNOLOGY

The Flawless Edge banding technology which has been created by Okan Meroglu during 2011-2012, and used by MIRA Inc., is separated from Seamless Edge Banding with usage of special multiple compounded glue. It is not needed to use pre-glued edge bands for the attaching process. Any conventional edge can be used for the purpose.

ADVANTAGES OF FLAWLESS EDGE BANDING TECHNOLOGY

* NO NEED OF SPECIAL PRE GLUED EDGE BANDS

Any type of conventional PVC, ABS, Acrylic, more over wooden or solid aluminium edge bands can be used in this process. This feature supplies a wide range to the customers

* WATER PROOF FEATURE AT EDGES

The Glue that is used at process supplies water proof feature at the edges where the band is attached to the piece. Furniture pieces can be cleaned by liquids or can be used at moisturized spaces.

* WIDE RANGE OF KEEPING TEMPERATURE

Peeling of edge bands from the furniture pieces is very hard. The process is durable between -40 and +100 degrees celcius. This supplies a big advantage at very hot container carrying.

* CONTINOUS GLOSSY AT EACH POINT OF EDGES

A continuous shiny surface can be obtained at cross of edges in case of available edge bands.

We are at service of our valued customers with 6 different door models at the moment.

We offer different standard stock colors in each of these models…. On the other hand, we are open to all alternative models and surface variations within the limits of availability of production according to the demands of our customers….

1. FLAT

The flat surfaced doors on which all types of handles can be mounted, all edges are produced with 1.3 mm thick ABS or solid Acrylic edge bands which are compatible with the specially produced surface color. Bright and Matte solid color all wood Stock colors are applicable.

2. FREE

Free model is produced in integrated appearance with ABS or massive Acrylic edge bands of 1.3 mm thickness which can be applied in handleless designs, with integrated profile handles on the back and matching edges with the specially produced surface color.

Bright and Matte solid color all wood Stock colors are applicable.

3. ARİNNA

Arinna model is developed with seamless integration of 3 parts and mounted special aluminum profile handles and integrated appearance with ABS or massive Acrylic edge bands of 1.0 and 1.3 mm thickness, which are compatible with the specially produced surface color of all sides.

Bright and Matte solid color all wood Stock colors are applicable.

4. ANİTTA

Anitta model is developed with the integrated appearance of 3 pieces, the middle panel angled by special process and mounted special aluminum profile handle and integrated appearance with 1.0 and 1.3 mm thickness ABS or solid Acrylic edge bands which are compatible with the specially produced surface color of all sides.

Glossy and Matte solid color suitable for angling process wood Stock colors.

5. COUNTRY

Country model is developed with seamless integration of 5 different parts with 2 thicknesses and integrated appearance with 1.0 and 1.3 mm thick edge bands which are compatible with the specially produced surface color of all sides.

Bright and Matte solid color all wood Stock colors are applicable.

6. ARUVA

Aruva model is developed with seamless integration of 3 pieces with the middle panel angled by special process in different 2 thicknesses and integrated appearance with ABS or massive Acrylic edge bands of 1.0 and 1.3 mm thickness, which are compatible with the specially produced surface color of all sides. Glossy and Matte solid or wooden surfaces which are available for angling process can be used.

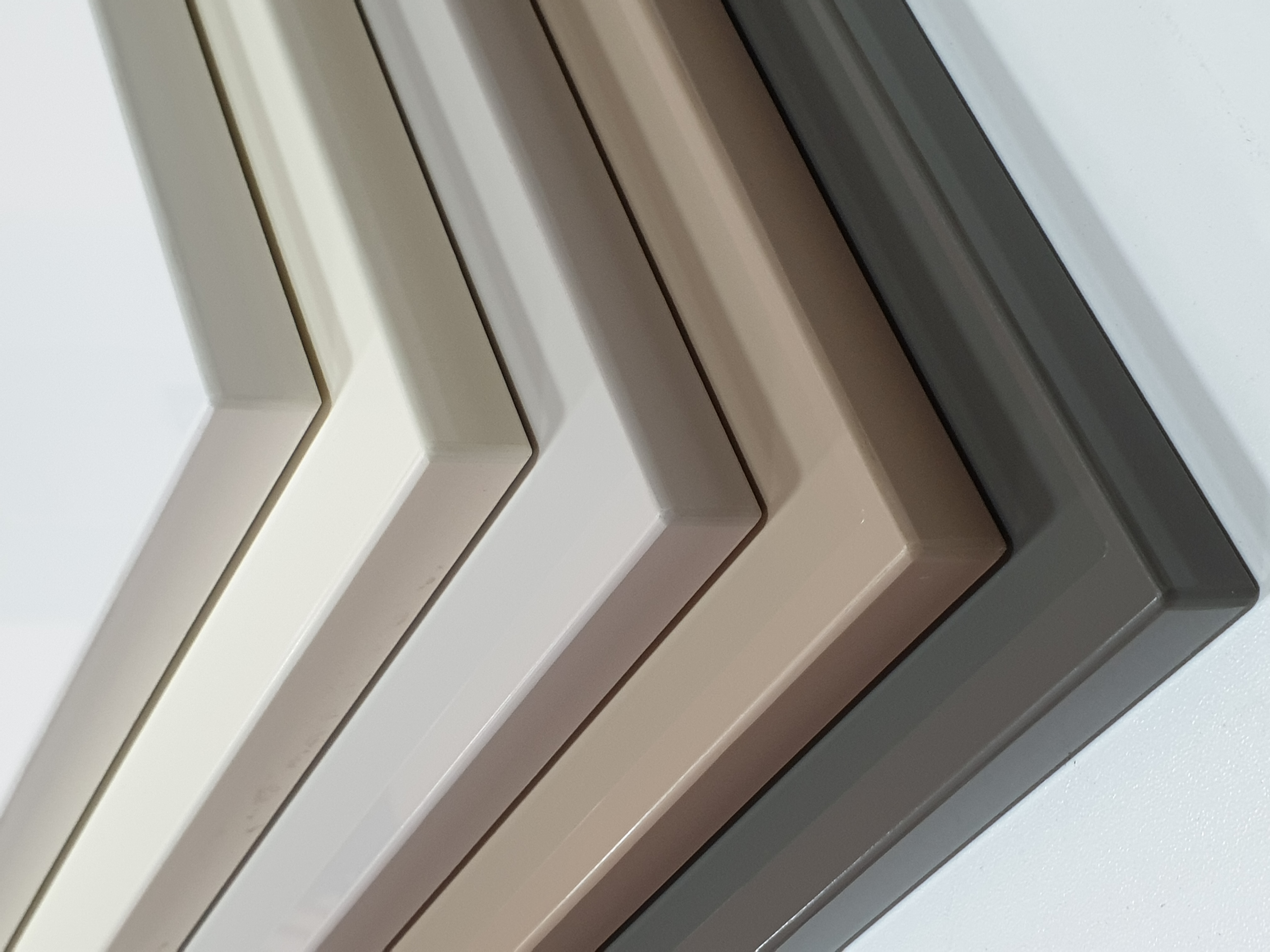

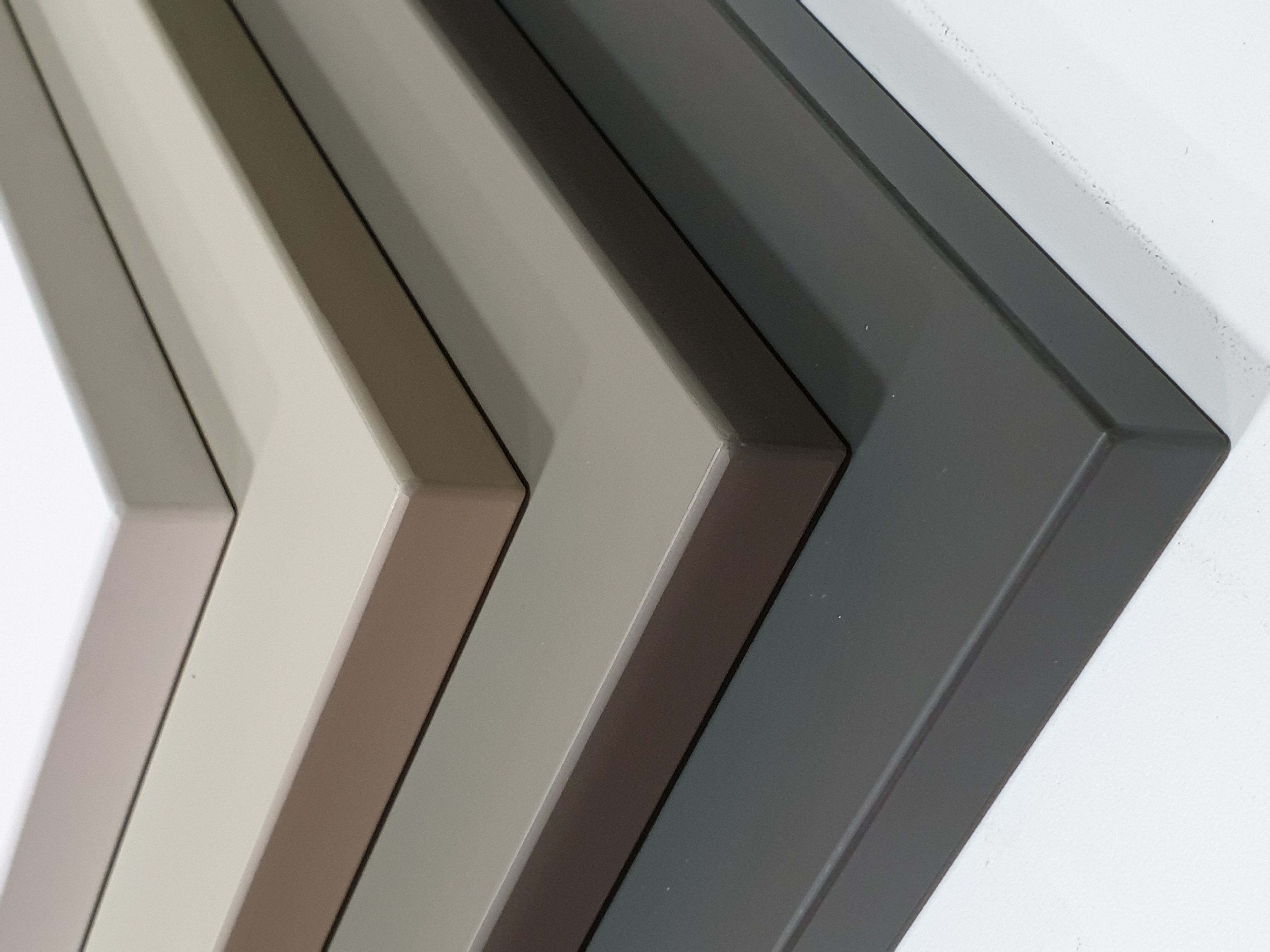

SURFACE COLORS AT STOCK

1. GLOSSY PLAIN SURFACE

Front side Scratch resistant acrylic, back side coated with polystyrene liner of similar color, MDF panels inside.

6801 – White

6802 – Cream

6803 – Cappuccino

6809 – Cashmere

6810 – Anthracite

Although the colors are constantly in stock, customer-specific color applications are made in high-volume projects.

2. SOFT TOUCH SILKY PLAIN SURFACE

Both sides are produced with scratch resistant matt silky surface coated with PET and MDF panels inside.

3717 – Lake White

3726 – Storm Gray

3728 – Rock Gray

3729 – New Gray

3730 – Mink

Although the colors are constantly in stock, customer-specific color applications are made in high quantity projects.

3. REGISTER EMBOSS WOODEN DESIGN SURFACE

Both sides are made of MDF or Chipboard panels coated with melamine or PET surface which gives the feeling of natural wood with register emboss.

2541 – Lugano

2545 – Cambridge

2546 – Richmond

3389 – Toledo

3397 – Natural Oak

Although the colors are constantly in stock, customer-specific color applications are made in high quantity projects.

Lacquered surface at furniture is one of the most qualified type. It can be applied as glossy or semi-matt or matt. At contrary, it has risk of color fading at sun shine and fragile against impacts. On the other hand it is very hard to catch the same tone of color in 2 different production lots.

There are artificial equivalent materials which can be used instead of lacquered surfaces at the market . Supplying the same is quality at the edges of these surfaced materials is very hard. Inner layers are seen unless they are not banded by PVC or ABS edge bands

The edges which are covered with edge bands by using hot melt glue cause a visible line which is between 60-100 micron thickness.

By time, this line becomes more visible because of outer effects. This obstacles a compact vision at edges.

We remove this unwanted line, by using a special glue at a special process.

Surfaces and edges of our products are more resistant against the impacts and we can remove the risk of color fading by using homogeneous colors..

We can obtain the most important feature of our process which is water proof at edges by this glue.

We present lacquered furniture components as prestigious as lacquered but more durable and resistant.